Material introduction of cosmetic aluminum-plastic tube

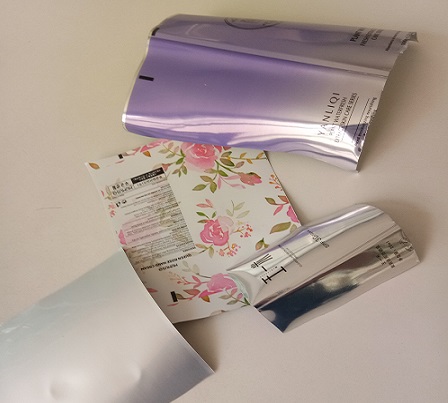

There are five main materials for cosmetic aluminum-plastic tubes: ordinary silver sheets, ordinary white sheets, high-gloss sheets (also called high-bright sheets), all-plastic transparent sheets, and fully-shaped white sheets. The five kinds of sheets have their own characteristics. The biggest difference is that the printing effect is different. The common point is that the printing effect is very realistic.

In addition, each material has different thicknesses. The most commonly used thickness specifications for cosmetic packaging are: 250μm, 270μm, 300μm, 330μm, 350μm, 400μm, and materials exceeding 400μm. The production process is very demanding, many manufacturers cannot make it. 350μm materials are commonly found in high-end cosmetic packaging, such as facial cleanser, sunscreen, etc. Sheets below 300 μm are generally found in hand cream tubes, toothpaste tubes, and the like.